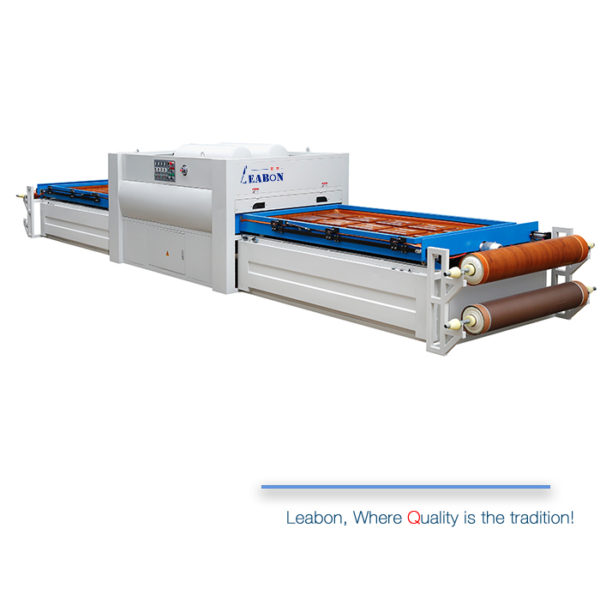

Vacuum press machine TOP-E260

TOP-E260 lamination vacuum press machine Features

1.It reduces the cumbersome operation steps and saves time;

2.Reduces the traditional trouble points and improves the working efficiency;

3.Upgrad the quality of each major component ,therefore improve the stability

4) This model is a double stations automatic operation mode.It can continuously operat the left and right two working tables. When the left table is working, right table places the workpiece; when the right table is working, the left table places workpiece . Maximize productivity without wasting time.

5) The operation interface adopts digital display control, which is simple and easy to understand. According to different PVC film materials, adjust the corresponding parameters (the parameter table is provided for reference when deliver from factory), just press the start button when working, which is quick and time-saving.

6)It equips with a high-speed vacuum pump with a rated speed of 100m3/h (optional) and an oversized vacuum tank. Therefore,can reach the required pressure in a short time, and the pumping speed is fast. So,shorten the molding time and improve the working efficiency

7) Two suction molding methods (pre-absorption molding and explosive suction molding) are available. The function can be freely chosen according to the material of the selected PVC film or the complexity of the sheet shape. Solve the phenomenon that the PVC material is broken and the line shape is not in place during the suction process.

8)It equips with special electric heating aluminum plate for heating, fast heating and uniform heat radiation. In addition,it equips with high-quality aluminum silicate board insulation, heat insulation and fireproof, and the thermal insulation effect is excellent. So,working at a constant temperature overcomes the problem of large temperature differences and high power consumption.

Introduction

Vacuum Press Machine TOP-E260, a revolutionary product that has been specifically designed for the home decoration industry. This machine is highly versatile and can be used in many applications such as the production of wardrobe doors, sliding doors and swing doors of panel furniture cabinets.

The TOP-E series is highly advanced and is capable of covering high-grade PVC and other decorative materials onto the surface of wooden boards. This results in making your furniture look more aesthetic and attractive.

One of the most significant features of the TOP-E260 is the reduction in cumbersome operation steps and the time saved in the manufacturing process. The machine has been designed to eliminate traditional trouble points and improve working efficiency. This upgrade in the quality of each component ensures higher stability, and the machine can perform incredibly well under tough working conditions.

The double-station automatic operation mode of the machine is an unbeatable feature that maximizes productivity. The left and right working tables continuously operate, allowing seamless transitions between tasks. When the left table is working, the right table places the workpiece, and vice versa. This feature allows for increased flexibility and quick throughput, making the manufacturing process more efficient than ever before.

In conclusion, the Vacuum Press Machine TOP-E260 is the perfect product for the home decoration industry and is optimally suited for the production of high-grade PVC and transfer film onto the surface of wooden boards. The machine's features of saving time, reducing cumbersome operational steps, and maximizing productivity make it a must-have for anyone in this industry.

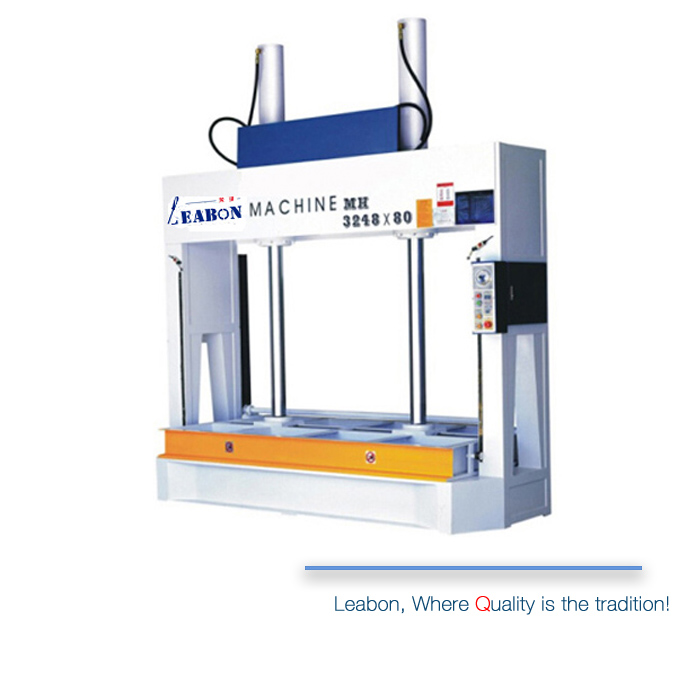

Quick press frame

Hubble lenses are made from high-grade methafilcon A hydrogel material. With 55% water content, UV protection, and a thin edge, they’re designed for easy insertion, all-day comfort and crystal clear vision.

Control Panel

The operation interface is controlled by digital display, which is easy to understand. In addition,according to the PVC film of different materials, adjust the corresponding parameters (the parameter table is provided for reference when leaving the factory),In short,it can just press the start button when working, which is quick and time-saving.

High speed direct connection motor

The worktable runs with high-speed direct-connected motor drive and fequency control. Therefore,the method of decelerating and stopping at high speed effectively prevents the plate displaced. In addition,it also shortens the running time and improves work efficiency.

Pipeless connection device

To clarify, the configuration of the pipeless connection device solves two problems: 1. In the case of cold weather, the traditional steel wire hose is easy to break because it doesn’t against freezing; 2. The traditional vacuum steel pipe has long-term wear and abrasion, Easy to scratch and cause air leaks.

Floating up heating way

It equips with the function of floating and heating of PVC film, which can solve the phenomenon of wrinkles or shaded area on the middle and low grade soft PVC film, and improve the uniformity of heat on the surface of PVC film.

High speed vacuum pump

It equips with a high-speed vacuum pump with a rated speed of 100m3/h (optional) and an oversized vacuum tank. Therefore, the required pressure can reach in a short time, and the pumping speed is fast. So, shorten the molding time and improve the working efficiency.

High speed vacuum pump

It equips with a high-speed vacuum pump with a rated speed of 100m3/h (optional) and an oversized vacuum tank. Therefore, the required pressure can reach in a short time, and the pumping speed is fast. So, shorten the molding time and improve the working efficiency.

OUR CERTIFICATES

| MODEL | TOP-E260 | |

|---|---|---|

| Selection | Standard edition | Extended version |

| Overall size | 9650*1780*1650mm | 11000*1780*1650mm |

| Working table | 2550*1300/1150*50mm | 3000*1300/1150*50mm |

| Working thickness | ≤50mm | ≤50mm |

| Total power | 23.8kw | 26.2kw |

| Consumption | 5kw/h | 5kw/h |

| Net Weight | 2000kg | 2500kg |