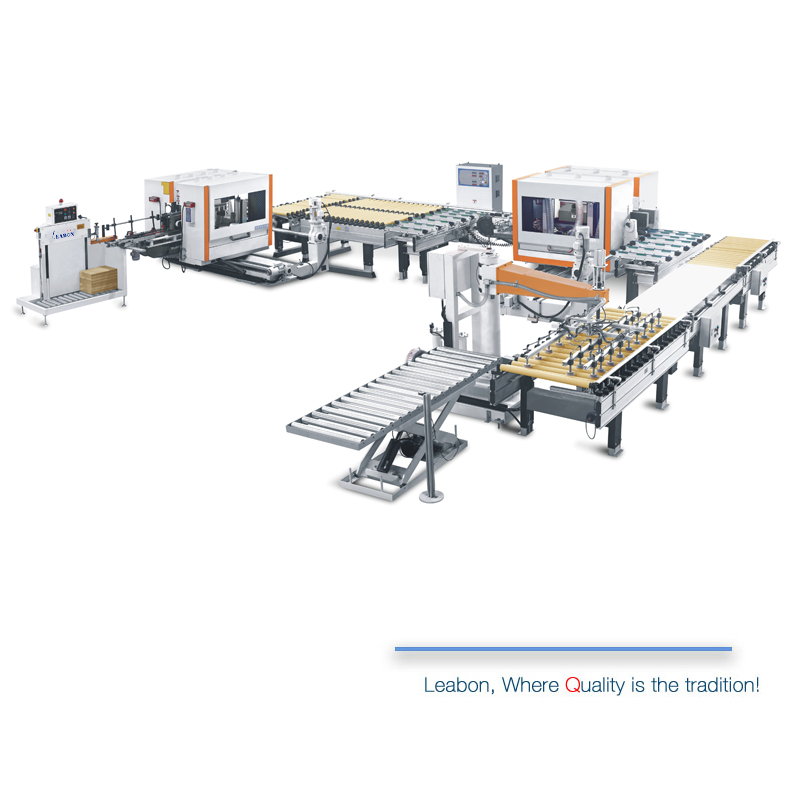

The Easy to Operate Double End Tenoner Line is Used for Automatic Board Loading and Unloading and Milling and Tenoning

Double End Tenoner Line Features

1. Main beam use aluminum, it is more stable and durable.

2. The roller thickness is more thick to make sure the load weight is enough for big size board. And the rubber surface of roller is optional.

3. We choose the famous brand for the main part to ensure the products quality.

4. We customize all kinds of woodworking machinery production lines for you according to the parameters you need.

Product Description

Double End Tenoner Line an advanced and highly automatic production equipment designed for maximum efficiency and productivity in woodworking applications. The Double End Tenoner Line is capable of increasing working efficiency by 100% when paired with a Double End Tenoner , effectively reducing labor costs, saving time , and improving overall production output.

With its highly sophisticated automation system, the Double End Tenoner Line enables the seamless integration of industrial processes, leading to reduced production costs, improved factory automatic production, and lower management expenses.

Equipped with a stable and durable aluminum main beam, the Double End Tenoner Line is built to withstand constant use and guarantee optimum performance for extended periods. Additionally, the roller thickness is increased to ensure a sufficient load weight capacity for working with lar ger boards, while The rubber surface of the rollers is optional, providing flexibility and customization.

At the core of the Double End Tenoner Line are components sourced from renowned brands, ensuring that each product is of the highest quality and built to stand the test of time. The result is an unmatched machine known for its unrivaled efficiency, durability, and reliability .

In Conclusion, The Double End Tenoner Line is An Exceptional Innovation that Combnes Efficience, Productivity, and AFFORDABILITY in Woodworking Operations. With IT s Automated Processses, Superior Build Quality, and Strong Performance Capabilities, it is a pursuit Options for businesses. Try the Double End Tenoner Line today and experience the future of woodworking.

CONVEYOR LINE DISPLAY

Feeding machine.

Double end tenoner Line schematic.

Double row power conveying roller table.

Power translation conveyor roller table.

Single row power conveying roller table.

Belt conveyors.

OUR CERTIFICATES

| Plate Specifications | |

| Plank length | 300-1500mm |

| Plank width | 280-500mm |

| Single piece thickness | 10-40mm |

| Piece weight | Max.30kg |

| Stacking weight | Max.400kg |

| Stacking height | Max.600 |

| Feeding and unloading speed | 6 times/min |