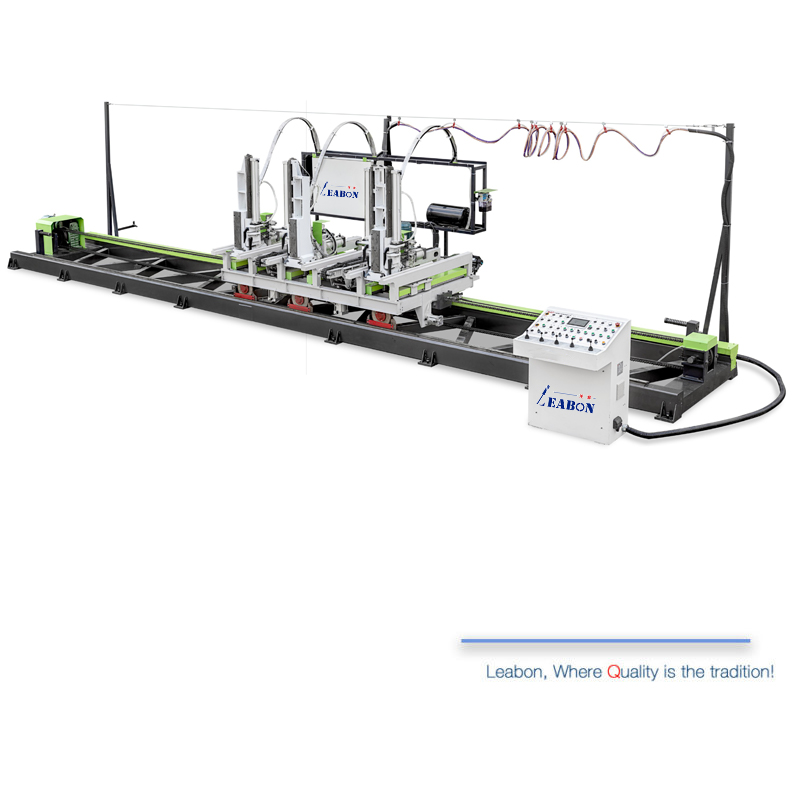

Furnitures Cabinets Carving Four-axis CNC Double-side Milling Machine JR-4TS by Precise and Efficient

Four-axis CNC Double-side Milling Machine JR-4TS Features

1. Germany Beckhoff advanced CNC system.

2.The cutting powertrain is imported from Europe. The main shaft is ground with German die steel and matched with Swedish SKF high-speed bearings.

3.Specially designed anti-loose function (the tool shaft can rotate forward and reverse).

4.The processing efficiency is 3-5 times higher than the traditional processing efficiency, the production cost is lower, and the efficiency is higher.

PARTS PICTURES

Independent research and development of operating software.

Independent research and development of operating software.

France schneider electric components.

One-piece high-speed mechanism design.

Heavy cutting mechanism.

Sanding mechanism.

European imported two-speed motor

Multi-directional pressure cylinder with fast valve.

Dust removal system adopts automatic spiral dust collection.

Introduction

This is designed to revolutionize the way fine milling, forming, tenoning and sanding of special-shaped products are done. Our Four-axis CNC Double-side Milling Machine is equipped with cutting-edge features that enable it to achieve unparalleled levels of precision, speed, and versatility.

One of the key features of this machine is the imported cutting powertrain from Europe. The main shaft is expertly ground with German die steel and comes with Swedish SKF high-speed bearings. The result is a powerful and robust mechanism that can handle even the toughest of jobs with ease. Additionally, its specially designed anti-loose function provides a unique tool shaft rotation experience that can rotate forward and reverse.

Our advanced CNC system boasts of a processing efficiency that is up to 3-5 times higher compared to traditional processing machines. This translates to lower production costs, higher efficiency, and faster turnaround times, ultimately resulting in a significantly better bottom line.

One of the highlights of our Four-axis CNC Double-side Milling Machine is its ability to overcome the inverted grain, chipping angle, and even plane special-shaped processing. It makes molding and sanding work feel effortless, quick and flawless. The shaft steering function enables you to choose the direction of the wood grain making for consistent and high-quality work.

Our machine is designed with simplicity and ease of use in mind. It is incredibly easy to operate and, thanks to its powerful control function, highly intuitive. You can achieve precise, accurate, and sensitive responses that make your work much more efficient.

our Germany Beckhoff advanced CNC system and Four-axis CNC Double-side Milling Machine is a winning combination of quality, technology, and efficiency. You can have peace of mind knowing that you are using cutting-edge technology that will transform the way you do CNC milling, forming, tenoning and sanding of special-shaped products.

OUR CERTIFICATES

| Model | JR-4TS |

| Processing length | 1500/2000/2500mm |

| Processing width | 15-400/15-600mm |

| Processing height | 200mm |

| Processing speed | 1-20m/min |

| Return speed | 100m/min |

| Tool shaft power | 7 .5kw*2 /8kw (2p/4p)*2 |

| Knife shaft speed | 9000r/min-3000r/min |

| Spindle diameter | φ40 |

| X-axis transmission power | 2kw/3kw |

| Y-axis transmission power | 1kw*4 |

| Total power | 38kw |

| System Configuration | Beckhoff |

| Mechanical Dimensions | 6600*3600*2200mm 7600*3600*2200mm 8600*3600*2200mm |

| Weight | 5.5t |