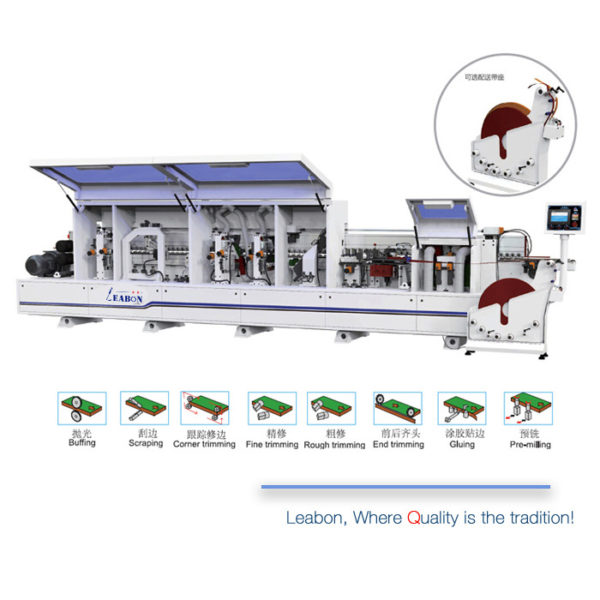

Automatic Straight line edge Banding Machine T-600 for Kitchen Cabinet and Wardrobe

China Automatic straight line edge banding machine T-600 Main Features

1. Our straight line edge banding machine use Taiwan Delta frequency controller, insured the duration and precision.

2. PLC use Tiawan Delta brand, air cylinder use SCM from Japan, INNA liner track, Honeywell limitation switch, all key parts we choose market tested best brands to try to guarantee our edge bander performance and let our customers can enjoy to use our machines.

3. Independent electric lifting up and down system, simple and convenient.

4. Precise encoder control, high speed.

5. Special polishing structure, motor angle can be universal adjusted, make the PVC/Acrylic/ABS/Veneer band polishing and buffing to the best.

6. Glue spray clean system is optional, it’s good to remove the glue and dirty on MDF/Wood panel during plastic banding process.

7. With such powerful functions and high efficiency, our straight line banding machine price is very competitive. As professional China banding equipment manufacture and supplier, We give factory price direct to final customer, you buy, you save!

8. PUR edge band function is optional to give you more durable, no gap banding experience!

9. Veneer/wood banding is optional to be installed!

Edge Banding Machine T-600Y

China Edge Banding Machine Factory

Automatic band change edge banding machine

Automatic belt changing and edge banding machine

FUNCTIONS INTRODUCTION

Equipped with double diamond blades, remove the possible waving texture on edge to achieve better edge banding affection.

Click edit button to change this text.

PRE-MILLING AND END TRIM

The buffing device adopts cotton material polishing wheel to sand the finished edge band more smoothly.

The gluing equipment adopts a special structure to distribute the glue evenly on the tape panel and the tape to ensure a stronger adhesion.

BUFFING AND GLUING

Fine and rough trim facilities are used to remove the extra material on band, it adopts mould automatically track and high frequency high speed motor, ensure the plain and smooth of work piece top and bottom parts.

Scraping units used to remove the texture which might happened during trim processing, guarantee the band to be smooth and plain.

FINE TRIM / ROUGH TRIM AND SCRAPPING

Product Description

Automatic Straight line edge Banding Machine T-600 With a range of functions including gluing, end cutting, rough trimming, fine trimming, scraping and buffing.

Designed to accommodate PVC, ABS and acrylic tape for MDF and Plywood edge banding work, the T-600 is ideal for thick tapes up to 2-3mm. Whether you are working on a large project or a small one, our edge banding machine delivers consistent and reliable performance due to the adoption of the best key components in the market.

Our edge banding machine uses a Taiwan Delta frequency controller to ensure both precision and durability. The PLC also adopts the Taiwan Delta brand, while the cylinder uses Japanese SCM, INNA linear guide rail, and a Honeywell limit switch, which are all top-rated components in the industry.

We also offer an independent electric lifting system that is simple and convenient to use. Our machine is equipped with a precise encoder control to ensure fast speed and accuracy.

The T-600 also features a special polishing structure that is equipped with a motor angle that can be adjusted universally, thereby allowing for perfect PVC/Acrylic/ABS/Veneer band polishing and buffing. The veneer/wood banding is optional and can be installed as per your requirements.

We understand the importance of optimizing your production workflow while minimizing downtime, and that’s why we’ve made our edge banding machine easy to use and maintain. Our product is designed to provide a perfect finish, minimize wastage, and boost productivity.

In conclusion, our Automatic Straight line edge Banding Machine T-600 has been designed with top-notch features that make it the best choice for your edge banding needs. Order now and experience the joy of using our machines.

OUR CERTIFICATES

| MODEL | T-600 |

|---|---|

| Motor Power | 9.5kw |

| Overall Dimension | 4600*1000*1600mm |

| Feeding Speed | 12-20mm/min |

| Panel Thickness | 12-60mm |

| Edge Banding Tape Thickness | 0.4-3mm |

| Panel Width | ≥ 80mm |

| Working Air Pressure | 0.6Mpa |

| Net Weight | 2300kgs |