Angled Conveyor Roll Table are Used in Woodworking Machinery for Edge Banding Machine and Sanding Machine production Lines etc.

Features of Angled Conveyor Roll Table

1. The speed is controlled by the inverter, which can match the high-speed edge banding.

2. There will be no standstill and stuck phenomenon during the workpiece transportation.

3. Imported rollers are used in the whole line, and the roller beats low, which ensures the smooth transmission of small-sized workpieces.

4. Use high-pressure-resistant aluminum frame and heavy-duty 288mm aluminum to ensure that the whole machine is stable and not deformed.

5. The electrical components use the Shihlin brand, which is easy to operate, stable and has a low failure rate.

Description

Our Angled Conveyor Roll Table is designed to facilitate the smooth and reliable transportation of workpieces from one end to the other. One of its key features is the speed control functionality which is enabled by an inverter that allows the speed to be matched with high-speed edge banding. This ensures that the workpieces move through the conveyor at a steady and consistent pace, eliminating any instances of stoppage or stalling.

In addition, our roll table is equipped with imported rollers that ensure the smooth transmission of small-sized workpieces. With a low roller beat, the transportation of delicate or fragile materials is fully supported, avoiding any unwanted impacts or damages along the way.

Built for optimal stability and durability, our Angled Conveyor Roll Table is constructed using high-pressure-resistant aluminum frames and heavy-duty 288mm aluminum supports. This ensures that the whole machine remains stable, even under heavy loads, and is not easily deformed. The use of premium-quality electrical components, such as the Shihl, further enhances the reliability and longevity of our roll table.

What sets our Angled Conveyor Roll Table apart is its customizable nature. We understand that different businesses have varying transportation and packaging processes, which is why we enable customers to customize their roll table specifications based on their unique needs. Whether it's a specific sizing requirement, conveyor angle, or roller configuration, we work closely with our customers to design and build a roll table that is tailored to their specific requirements.

In conclusion, our customizable Angled Conveyor Roll Table is an innovative transportation solution designed to offer businesses optimal reliability and efficiency in their daily operations. With its high-quality components and customizable options, our roll table guarantees superior performance and long-lasting durability, making it an ideal investment for any business looking to streamline their production processes.

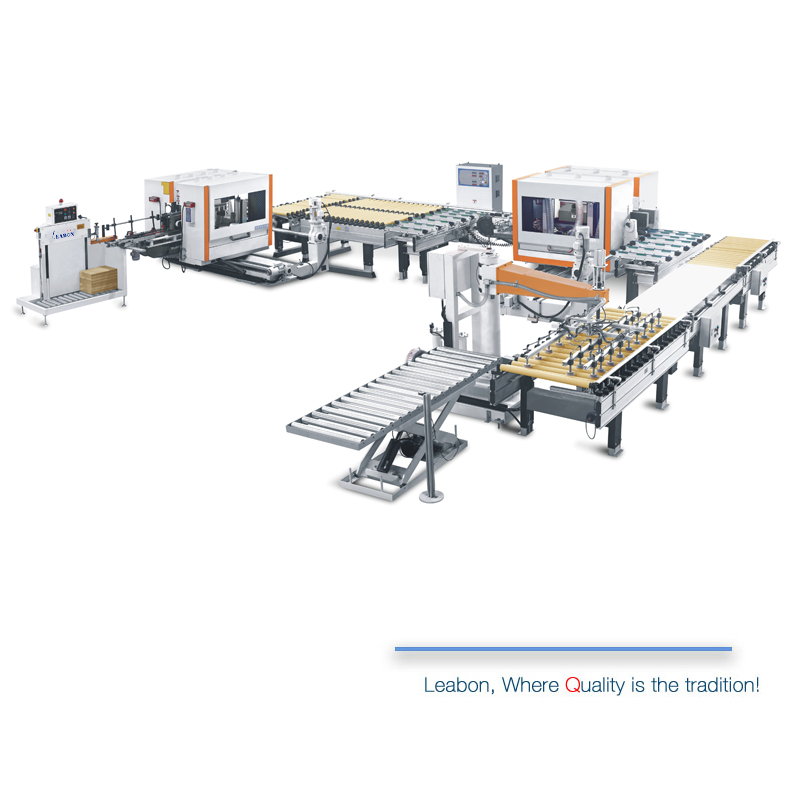

Machine Display

Angled Conveyor RC8026PY-X

Angled Conveyor RC6013PY-X

Practical Application

Our Certificates

| Model | RC6013PY-X | RC5026PY-X | RC8026PYX |

| Workpiece length | 300-2400mm | 300-2400mm | 300-2400mm |

| Workpiece width | 300-1200mm | 300-1200mm | 300-1200mm |

| Workpiece thickness | 10-70mm | 10-70mm | 10-70mm |

| Loading capacity | Max.50kg | Max.50kg | Max.50kg |

| Working height | 900士50mm | 900士50mm | 900士50mm |

| Feeding speed | 0-24m/min | 0-24m/min | 0-24m/min |

| Overall size | 6000x1500x1300mm | 5000x3000x1300mm | 8000x2800x1200mm |

| Weight | 1200kg | 2000kg | 1500kg |

| Total power | 3 .3kw | 6kw | 4.1kw |